Innovation Hub: From 3D-Printed Titanium Wheels to Sustainable Construction Walls, Vista is a Center for Innovative Manufacturers

Welcome to Innovation Hub, a new series celebrating the extraordinary companies that call Vista home. From healthcare tech to precision medicine, electronics, AI, cybersecurity, manufacturing and more, this series takes a deeper dive into the innovative industries that make up the collaborative culture in this diverse city.

Did you know that the world’s first 3D printed titanium wheel was designed and made in Vista? Vista-based HRE Wheels, in partnership with GE Additive, recently unveiled the first titanium wheel created using EBM technology (a type of 3D printing). Known as HRE3D+, this new prototype wheel shows what the future of wheel technology will bring and how advanced materials like titanium can be harnessed to create complex designs.

The goal of the “HRE3D+” project is to test the capabilities of additive manufacturing in a practical application and to create a highly-sophisticated wheel design with an elusive material like titanium.

“We continually invest in new capabilities,” said HRE’s President & CEO Alan Peltier. “We just invested another $250,000 at the end of 2018 into expanding our robotic cell system. This automated system allows us to machine wheels 24/7 ‘lights out’ (unattended). This system in total is a $1 million-plus investment that has improved our quality and capacity significantly. But we aren’t just focusing on current technologies; we are also aggressively pursuing new materials like titanium and composites, and new manufacturing methodologies like additive manufacturing (3D printing). We want to ensure we maintain our place at the top as we move into the future.”

McLaren P1 with 3D-printed wheels designed and built by HRE in Vista

HRE, which was established in 1978, makes custom performance wheels for automotive enthusiasts and professional race teams. The company sells its wheels to high net-worth automotive enthusiasts that own exotic cars (Porsches, Ferraris, Lamborghinis, McLarens, etc…), with approximately 40% of its products exported to customers around the world. These high-end wheels are very exclusive, build-to-order performance wheels that average $10,000 for a set of four, but can be optioned significantly higher.

“We define specifications with the customer – style, fitment, finish, vehicle, etc. – to create a custom order that goes through our manufacturing process and ships to customers in typically four-to-six weeks. We do all of the design and engineering in-house as well. We like to control as many aspects as possible to ensure the utmost in quality and performance,” said Peltier, who first joined HRE as the lead engineer in 1999, and then became president in 2009 and CEO in December 2018.

Alan Peltier

Peltier said HRE has chosen to stay and grow in Vista for several reasons, including a large employee base able to fill entry-level to experienced technical roles.

“We also think Vista is very supportive as a city toward its local businesses,” he said. “They help us through any certifications, regulations, etc…. We have a massive annual Open House and attendance has become so large (approximately 5,000 attendees) that we need to work with the city on planning and permits, and Vista is always very supportive.”

“Vista is definitely a manufacturing hub,” Peltier added. “We feel there are many small and large manufacturers doing varied manufacturing in Vista. Some are fairly low-tech, but others are using very innovative technology and create very high-tech products to support aerospace and biomedical. HRE counts itself among this group as we do more and more high-tech manufacturing every day.”

Peltier said HRE has grown about 20% over the past few years and has added about 10 employees, bringing its current team to approximately 50.

“I came from the aerospace industry 20 years ago, and I saw this company had the potential to be something truly special,” he said. “It has taken a long time, but we’ve built a team and a culture here that really believes in being the best at what we do, and we believe in building a brand that is world renowned for quality and exclusivity. We continually push ourselves to improve everything every day and do all of this with a culture based on trust. Integrity and capability are the keys to being a part of our team.”

With more than 21.3 million square feet of commercial, retail, and industrial space, Vista is home to several other innovative manufacturing and R&D firms besides HRE Wheels. From medical devices to aerospace instruments, computer electronics, machinery and more, Vista is recognized as a leader in precision manufacturing and high-quality specialty products. As a regional hub for advanced manufacturing, Vista supplies a significant share of the region’s high-value products, helping to fuel the region’s export pipeline. With more than 10,555 jobs, manufacturing represents roughly 21% of employment in Vista.

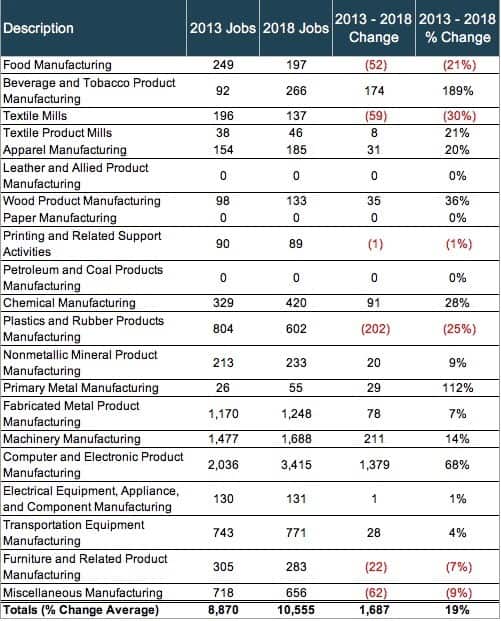

According to the San Diego Regional Economic Development Corp., the number of manufacturing jobs in Vista is 163% above the national average. The average annual salary in 2018 for manufacturing jobs in Vista was $100,705, compared to the national average of $83,752. Vista also experienced a 19% growth in manufacturing jobs between 2013-2018, compared to the national average of 4.5%.

Breakdown of manufacturing industries in Vista, courtesy of the SD Regional EDC

“Vista’s diverse manufacturing sector not only provides high-paying jobs for our community but it also fosters innovation and entrepreneurship,” said Kevin Ham, Vista’s Director of Economic Development. “We want to continue to support and bring more innovators to our city. That, in turn, has a positive economic impact on surrounding businesses, from our hotels to our markets, banks, schools, coffee shops, breweries, and others.”

One of those leading innovators is Jeffrey L. McCain, Founder and CEO of Vista-based McCain Manufacturing, which specializes in precision sheet metal fabrication. The company’s flagship product is McCain Walls, which are sustainable walls that are made from 100% recyclable metals, are reusable, and have various applications across many industries from casinos to airports, healthcare, commercial buildings, office spaces, warehouses, and more. The company’s modular walls are designed to reduce building material waste like drywall from landfills.

The company’s 100,000- square-foot LEED-certified facility in Vista houses world-class automated systems and smart and sustainable practices.

“Our walls are completely manufactured at our plant in Vista, including the selected wall finish customers choose,” McCain said. “The parts are delivered to the job site where it requires minimal labor, noise, and disruption. The walls are easy to install and go up extremely fast. Most people cannot even tell the difference from the traditional walls they are used to. Our walls are being used by customers coast-to-coast. Many airports, including San Diego, are very impressed with it; in fact, they refer to it as the miracle wall.”

McCain Manufacturing was created in 2016 after McCain sold his successful traffic control equipment company, McCain. Inc. (also in Vista).

Creative marketing graphics on temporary McCain Wall at the San Diego International Airport

“The purpose and the niche that we chose for McCain Manufacturing was to come up with a product that was environmentally friendly, could be manufactured locally, and that could be marketed to consumers everywhere. It is a solution to the building industry that has heavily relied on drywall,” said McCain, explaining that while drywall was invented over 100 years ago and is very cost efficient, it is harmful to the environment and has negative effects on human life. “There are states that will not allow for scrap drywall to be put in landfills, due to the fact it contaminates water tables, among other things.”

McCain Manufacturing, which was recently awarded a patent for its product, has customers around the nation. McCain said most of the company’s recent efforts have been in R&D, as well as developing other uses for its walls.

McCain Manufacturing Owner Jeff McCain

“We are currently making outdoor weatherproof sheds and we are introducing a new line of ADU’s (Accessory Dwelling Units),” he said. “We have been working with many cities, including Vista, on different applications for the walls. Just imagine an ADU being installed in someone’s backyard in a matter of weeks instead of months, made of recyclable materials, that requires very

little maintenance, is high-quality, and affordable in price. In fact, if a customer decides after a few years they don’t need it or would prefer to have a pool, it could be taken down and reinstalled in another location. It’s a one-of-a-kind type solution to the affordable housing crisis.”

As for Vista, McCain said there’s no other place he’d rather have his businesses.

“I’ve been doing business in the City of Vista at multiple locations for well over 30 years,” said McCain, who was awarded Entrepreneur of the Year for San Diego by Ernst & Young in 2009. “They have always taken the attitude of ‘what can we do to help you grow your business.’ They were that 30 years ago, and they still have the same attitude. Over the years, the city has attracted many other manufacturers and supporting type businesses that make it ideal for companies like McCain Manufacturing to be successful.”

McCain’s ultimate goal is to create an environmental reusable product, as well as a replacement industry for traditional construction while keeping manufacturing in the US.

“I’ve been fortunate and I’ve had much success in the past, and to be able to manufacture a product that I am very passionate about and provides a huge solution to a growing problem with minimal negative side effects to the environment is something that we really believe in; we feel that we can make a difference in this world,” he said. “We like to think that we are helping to save the planet one wall at a time.”

Media contact for the City of Vista:

Kevin Ham

Economic Development Director

kham@cityofvista.com